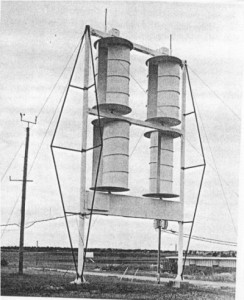

Another type of turbine developed at about the same time as the Darrieus was the Savonius turbine, developed in Finland by S. J. Savonius. This is anothervertical axis machine which needs no orientation into the wind. Alternative energy enthusiasts often build this turbine from used oil barrels by cutting the barrels in half lengthwise and welding the two halves back together offset from one another to catch the wind. A picture of a somewhat more advanced unit developed at Kansas State University, Manhattan, Kansas, is shown in Figure.

The tower of the KSU Savonius was 11 m high and 6 m wide. Each rotor was 3 m high by 1.75 m in diameter. The rotors were connected together and drove a single 5 kW, three-phase, permanent magnet generator. At the rated wind speed of 12 m/s, the rotor speed was 103 r/min, the generator speed was 1800 r/min, and the frequency was 60 Hz. Output voltage and frequency varied with wind speed and load, which meant that this particular turbine could not be directly paralleled with the utility grid. Applications for this asynchronous (not synchronized with the utility grid) electricity are limited to electric heating and driving three-phase induction motors in situations which can tolerate variable speed operation. These include heat pumps, some water pumps, and fans. Such applications consume large quantities of electrical energy, so variable frequency operation is not as restrictive as it might appear. Asynchronous systems do not require complex blade pitch, voltage, and frequency controls, hence should be less expensive.

The main advantages of the Savonius are a very high starting torque and simple construction. The disadvantages are weight of materials and the difficulty of designing the rotor to withstand high wind speeds. These disadvantages could perhaps be overcome by good engineering if the turbine efficiency were high enough to justify the engineering effort required. Agreement on the efficiency of the Savonius turbine apparently has finally been reached a half century after its development.

Savonius claimed an efficiency of 31 per cent in the wind tunnel and 37 per cent in free air. However, he commented: “The calculations of Professor Betz gave 20 % as the highest theoretical maximum for vertical airwheels, which under the best of circumstances could not produce more than 10 % in practical output.” The theoretical and experimental results failed to agree. Unfortunately, Savonius did not specify the shape and size of his turbine well enough for others to try to duplicate his results.

A small unit of approximately 2 m high by 1 m diameter was built and tested at Kansas State University during the period 1932-1938. This unit was destroyed by a high wind, but efficiencies of 35 to 40 % were claimed by the researchers. Wind tunnel tests were performed by Sandia on 1.5 m high by 1 m diameter Savonius turbines, with a maximum efficiency measured of 25 % for semicircular blades.

Different blade shapes which were tested at the University of Illinois showed a maximum efficiency of about 35 %. More Savonius turbines were tested at Kansas State University, with efficiencies reported of about 25 %. It thus appears that the Savonius, if properly designed, has an efficiency nearly as good as the horizontal axis propeller turbine or the Darrieus turbine. The Savonius turbine therefore holds promise in applications where low to medium technology is required or where the high starting torque is important.

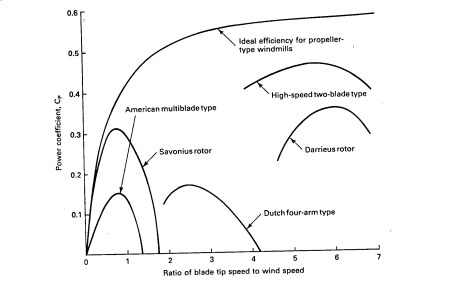

A chart of efficiency of five different turbine types is shown in Figure. The efficiency or power coefficient varies with the ratio of blade tip speed to wind speed, with the peak value being the number quoted for a comparison of turbines. This will be discussed in more detail in Chapter 4. It may be noticed that the peak efficiencies of the two bladed propeller, the Darrieus, and the Savonius are all above 30 %, while the American Multiblade and the Dutch windmills peak at about 15 %. These efficiencies indicate that the American Multiblade is not competitive for generating electricity, even though it is almost ideally suited and very competitive for pumping water.

The efficiency curves for the Savonius and the American Multiblade have been known for a long time. Unfortunately, the labels on the two curves were accidentally interchanged in some key publication in recent years, with the result that many authors have used an erroneous set of curves in their writing. This historical accident will probably take years to correct.

Another vertical axis machine which has interested people for many years is the Madaras rotor. This system was invented by Julius D. Madaras, who conducted considerable tests on his idea between 1929 and 1934. This concept uses the Magnus effect, which refers to the force produced on a spinning cylinder or sphere in a stream of air.

The most familiar example of this effect is the curve ball thrown by a baseball pitcher. The Madaras rotor is a large cylinder which is spun in the wind by an electric motor. When the wind is from the left and the cylinder is spinning counterclockwise as shown in Fig. 9, the cylinder will experience a lift force in the direction shown. There will also be a drag force in the direction of the wind flow.