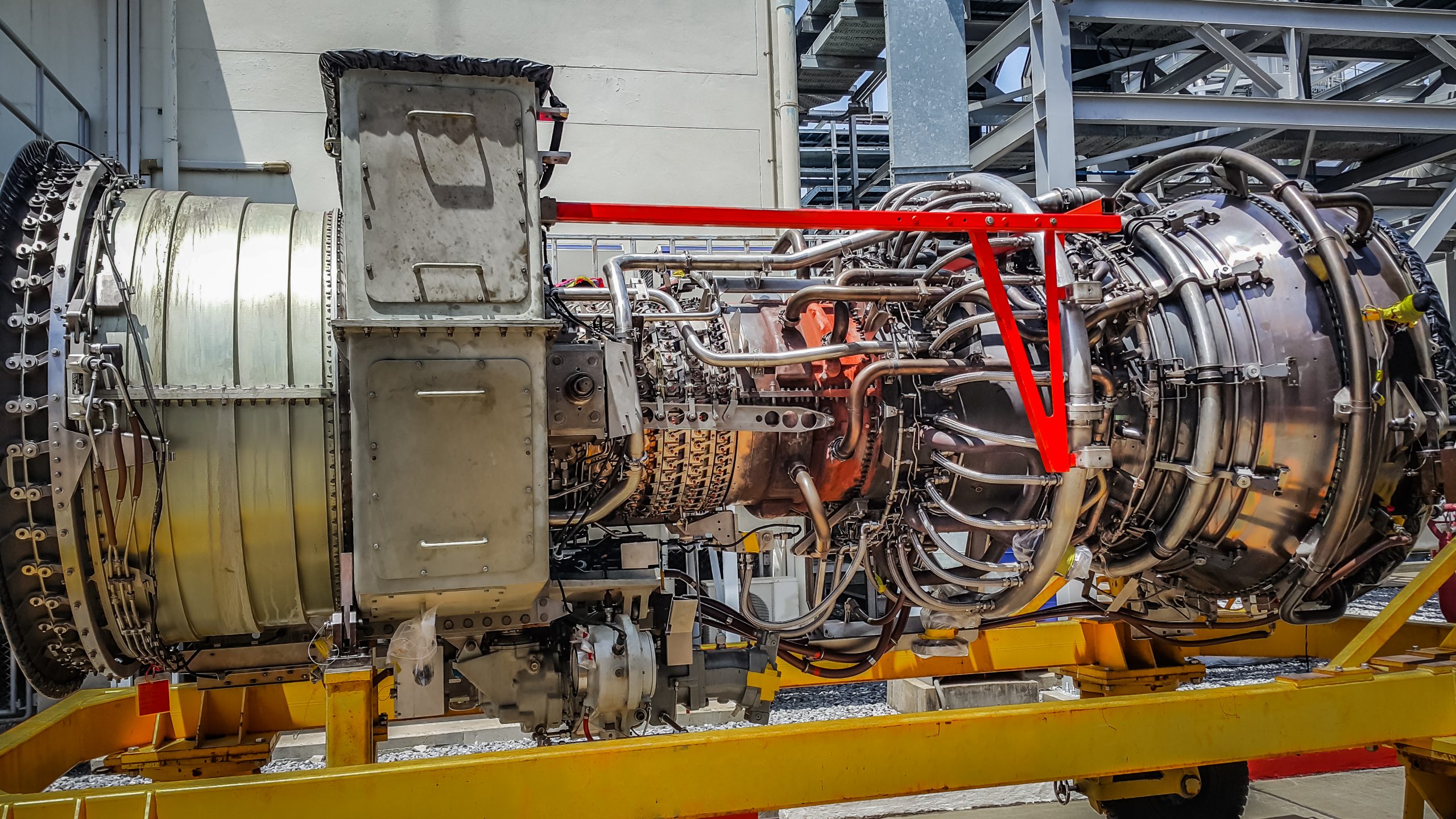

Engineering advancements pioneered the development of gas turbines in the early 1900s, and turbines began to be used for stationary electric power generation in the late 1930s. Turbines revolutionized airplane propulsion in the 1940s, and in the 1990s through today have been a popular choice for new power generation plants in the United States.

Gas turbines are available in sizes ranging from 500 kilowatts (kW) to 250 megawatts (MW). Gas turbines can be used in power-only generation or in combined heat and power (CHP) systems.

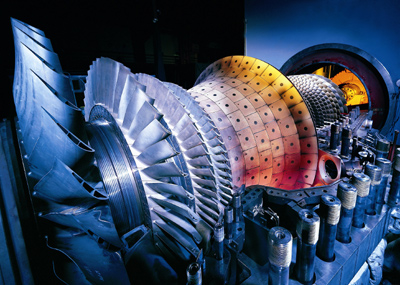

The most efficient commercial technology for central station power-only generation is the gas turbine-steam turbinecombined-cycle plant, with efficiencies approaching 60 percent lower heating value (LHV).1 Simple-cycle gas turbines for power-only generation are available with efficiencies approaching 40 percent (LHV). Gas turbines have long been used by utilities for peaking capacity. However, with changes in the power industry and advancements in the technology, the gas turbine is now being increasingly used for base-load power.

Gas turbines produce high-quality exhaust heat that can be used in CHP configurations to reach overall system efficiencies (electricity and useful thermal energy) of 70 to 80 percent. By the early 1980s, the efficiency and reliability of smaller gas turbines (1 to 40 MW) had progressed sufficiently to be an attractive choice for industrial and large institutional users for CHP applications.

Gas turbines are one of the cleanest means of generating electricity, with emissions of oxides of nitrogen (NOx) from some large turbines in the single-digit parts per million (ppm) range, either with catalytic exhaust cleanup or lean pre-mixed combustion.

Because of their relatively high efficiency and reliance on natural gas as the primary fuel, gas turbines emit substantially less carbon dioxide (CO2) per kilowatt-hour (kWh) generated than any other fossil technology in general commercial use.