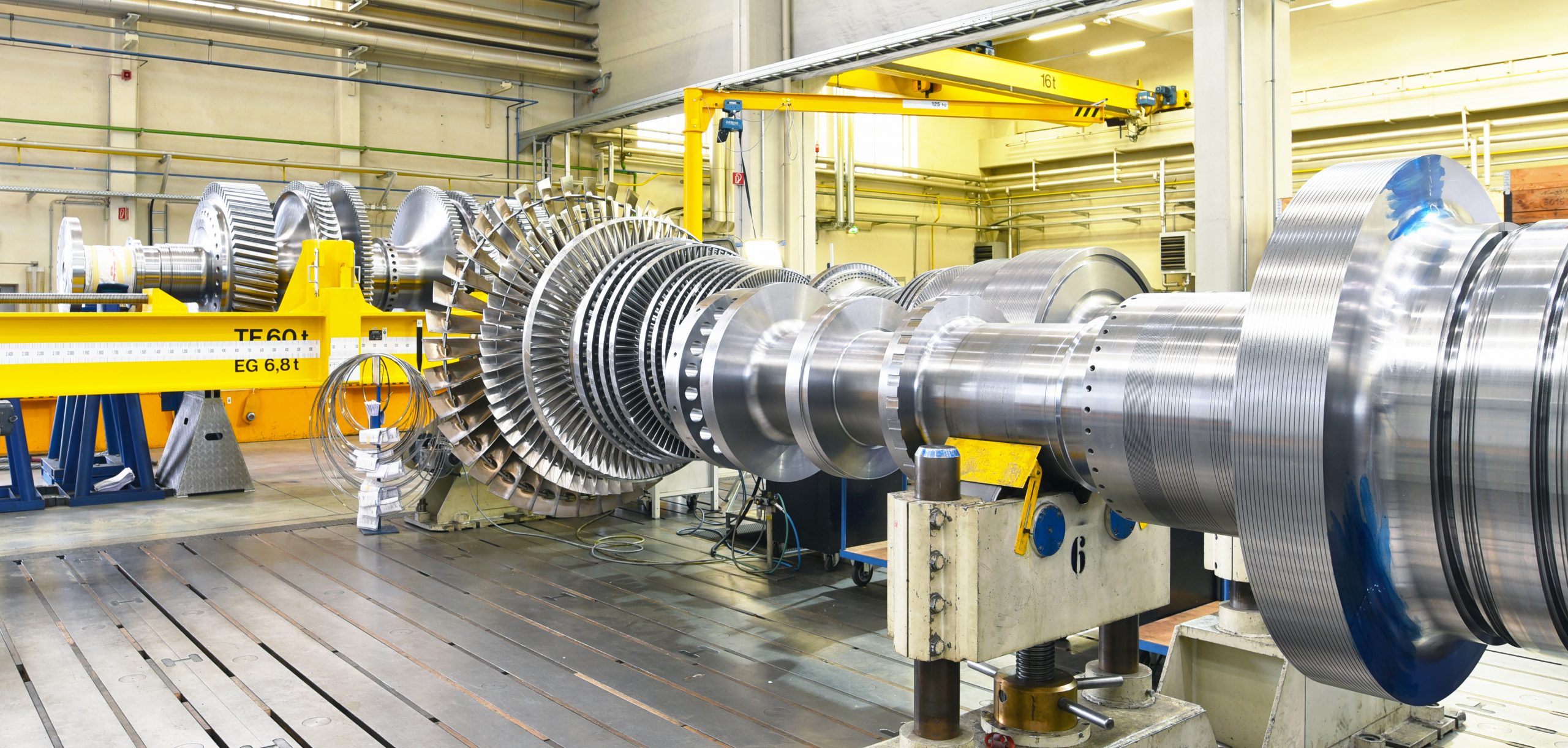

The whirring blades of Hagshaw Hill, Scotland’s oldest commercial wind farm, fell silent last year. Cranes dismantled the turbines that had faithfully generated electricity for 28 years. This scene is becoming increasingly common worldwide as the first wave of wind turbines, built in the late 1990s and early 2000s, reaches retirement.

Hagshaw Hill exemplifies the challenge: while replacing these giants with taller, more efficient models that generate ten times the electricity is exciting, what happens to the old blades?

The Blade Recycling Conundrum

While 85-95% of a wind turbine (steel, aluminum, copper) is easily recycled, the blades pose a significant problem. Made from fiberglass and coated with tough epoxy resin to withstand harsh weather, they’re difficult to break down for traditional recycling.

Landfilling blades, a common practice, is becoming less feasible. Countries like Germany and the Netherlands have banned it due to limited space and environmental concerns. Innovative ideas like repurposing blades into playgrounds exist, but with a staggering 43 million tonnes of blade waste predicted by 2050, a large-scale solution is urgently needed.

Breaking Down the Barriers

Scientists and startups are tackling this head-on, focusing on separating the fiberglass from the resin. Dr. Claire Barlow, a sustainability engineer at the University of Cambridge, emphasizes, “At the end of life, to get value from the materials, we need to separate the fibers from the resin.”

Promising Solutions Emerge

One approach gaining traction utilizes a technique developed by the University of Strathclyde’s Project PRoGrESS. They shred blades and feed them into a superheated air stream, separating and allowing reuse of the glass fiber. Their pilot plant, expected to be operational this year, has faced challenges due to rising material costs.

Similar solutions are being explored elsewhere. Vestas, a leading wind turbine manufacturer, announced a method using a liquid chemical solution to break down blades into reusable materials potentially suitable for new blades. This method boasts scalability and avoids high temperatures, aligning with Vestas’ claim of recycling 475 blades in 2022.

A Second Life for Old Blades

Successful recycling technologies could not only address future waste but also tackle the existing backlog of blades in landfills and storage facilities. At Hagshaw Hill, for example, several turbines await ScottishPower Renewables’ decision on their fate.

Building a Sustainable Future for Wind Energy

The future might see wind turbine blades built from materials easier to recycle than fiberglass and epoxy resin. However, for now, the focus is on scaling up these promising recycling technologies without harming the environment. As Dr. Barlow aptly states, “That really is the silver bullet” for a sustainable future of wind energy.