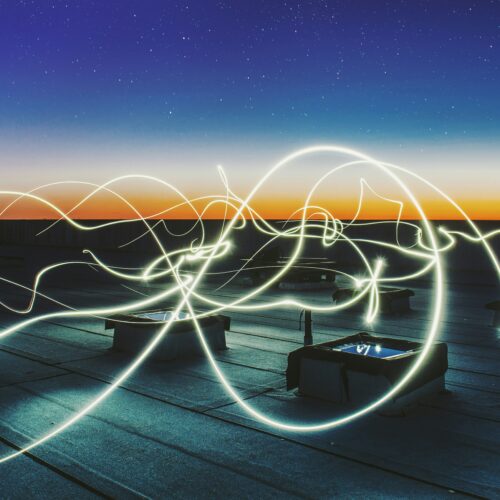

The turbine creator Henrik Stiesdal is little in the shadows of enormous curves of steel, enjoying employees bonded towers that will certainly be rooted to the seabed. This factory in the Danish countryside has actually produced thousands of masts for wind generators whose blades can stretch more than 500 feet. It’s a vital contribution to a global wind transformation that’s providing power to countless residences worldwide.

Quickly the factory will certainly approach a new task, manufacturing components for a various type of generator, created by Stiesdal, that bobs on the ocean blue. These frameworks guarantee to place the solid, regular gusts that blow over deep waters accessible for the first time. The generators now found around Denmark, England, as well as the various other coastlines of the North Sea are made for shallow water and need large underwater frameworks to secure them in place. “Regular places do not have superficial water near populace facilities– they have deep water,” claims Stiesdal, a fabulous turbine creator and former executive at some of Europe’s largest wind firms. This circumstance provides several seaside places unsuitable for wind power. “We could power California sometimes over with their offshore source,” he says, “however it all needs to be drifting.”

If the future generation of wind ranches can drift, as well as if costs can be maintained low, it might usher in an age of almost endless, emission-free power. The International Energy Company (IEA) estimates that drifting wind turbines could assist supply adequate electrical power to satisfy the globe’s electrical energy needs 11 times over, based on predicted power need in 2040.

At 63, Stiesdal has taken every step in the contemporary evolution of wind power. As a boy, he made the initial generator and also later on participated in the introduction of the very first overseas wind farm, producing what’s currently among the fastest-growing forms of renewable energy. He’s seen international wind capability expand from virtually nothing in 1978 to greater than 600 gigawatts today, according to Bloomberg NEF infortmation.

Drifting Offshore Wind Turbines

As 2019 ended, concerning three-quarters of worldwide offshore capacity lay in Europe, mainly clustered around the U.K. and also Germany. This local prominence owes partially to the North Sea’s family member commonplace. Although comparable waters off China, Vietnam, and the eastern U.S. seaboard could at some point add even more wind farms making use of recognized modern technology, there’s greater prospective farther offshore. A lot more areas, including The golden state, Japan, as well as South Korea, have heavy power requirements, large aspirations to lower exhausts, as well as deep seas. In addition to that people have a tendency to grumble– noisally– about generators within sight of the coast. The ocean blue isn’t in any individual’s backyard.

Now Stiesdal is amongst those bringing about the floating-energy future. With offshore wind power significantly competitive with the price of nonrenewable fuel sources, growth right into much deeper waters might help free electrical grids of carbon emissions forever. “I had some bad moments thinking of the environment,” he claims. “The politicians will not resolve it. We need to resolve it ourselves.”

After he completed senior high school in country Denmark in the late 1970s, Stiesdal read about a nearby instructors’ university that was running an experiment to produce electricity from wind. He chose to attempt making a model generator in his family’s residence. He developed the first blades from steel and state-of-the-art nylon, working with the living-room flooring as his mother weaved on the couch.

The initial turbine he made was little sufficient that he can lift it with one hand. “When you got it spinning, it reached be alive, and you could feel all the small things in the wind,” Stiesdal recalls. “I was hooked.” It functioned well enough that he got a regional machinist to aid him develop a larger version that can offer power to his household’s farm.

A couple of years later, with more tinkering, he ‘d scaled approximately a point that it took 2 individuals to lug a blade. Executives from a neighborhood maker of hydraulic cranes came to have a look at his generators and also drink coffee. Changing costly, polluting fossil fuels with wind made good sense, also before climate adjustment became a pressing concern.

Stiesdal struck a licensing contract with the executives, which ultimately resulted in mass production and also later on a full rebranding as Vestas Wind Equipment A/S. The firm is the world’s largest wind generator manufacturer, with greater than $13 billion in profits in 2014. In its official business history, Vestas recognizes that its earliest initiatives– made to look like an egg whisk– stopped working to create sufficient electrical power to be practical. But Stiesdal’s models, the firm creates, are “essentially the exact same three-blade design made use of today.” As well as not just by Vestas: The same arrangement is made use of throughout the globe, by ratings of makers.

The developer worked with Vestas up until the mid-1980s, after that took place to a job at Bonus offer Energy, a Danish wind turbine business that was later bought by German commercial titan Siemens AG. That’s where he coordinated the intro in 1991 of the first offshore turbines able to stand up to severe problems mixed-up. “He’s like the godfather of wind,” states Tom Harries, that analyzes the market for BNEF.

Offshore turbines are currently scattered all over the world by the thousands, the item of billions of bucks of financial investment. The current and largest, an 860-foot-high equipment from Siemens Gamesa that will be tested next year in north Denmark, is practically as high as New York’s Chrysler Structure. As wind turbines have actually multiplied and spread out, prices have actually fallen greatly– down greater than 60% in the last decade.

In the following 20 years, the IEA expects the overseas market to attract $840 billion– virtually as much investment as gas. A lot of the most significant designers now are European power firms such as Denmark’s Orsted, Germany’s RWE, and Spain’s Iberdrola, which have significantly changed away from nonrenewable fuel sources. In China, the second-biggest overseas market after Europe, companies such as China Ming Yang Wind Power Team Ltd. and Xinjiang Gold wind Science & Innovation Ltd. have marketed numerous wind turbines domestically.

” The cork is coming off the bottle,” Stiesdal states. “With the price decreases we’re seeing, we’re outcompeting with all type of fuels. You can not develop gas-fired plants and also coal plants as well as nuclear plants that can match wind.”

A successful floating platform would certainly push open brand-new wind markets as well as possibly produce billions of dollars of generator contracts. The earliest looks of this future, actually, come from pilot tasks started by fossil fuel companies, which have long proficiency in drawing out resources from the seabed using platforms. Designs for wind variations vary, yet one of the most widespread use steel or concrete to sustain a solitary wind turbine. Some designs have a tube form, with a generator on one corner. Others look more like a buoy, with a turbine bobbing on top. The primary design difficulty is maintaining the equipment in the appropriate position; a small rotation can move the blades out of the wind. The styles rely upon cables and supports to maintain the systems in the best area. Resilient wind turbines fitted with anchors can be produced at sea in water as deep as 1,000 meters (3,281 feet).

Opening Up Much Deeper Shorelines to Wind Turbines

On the economic side, “the essential bottleneck is the drifting foundation,” claims Jason Cheng, taking care of partner at exclusive equity company Kerogen Funding. “We assume that’s where a great amount of the worth will be recorded.” Kerogen mostly purchases nonrenewable fuel sources, but it’s taken a risk in Ideol, a French platform developer. Cheng says he liked that drifting wind makes use of tried and tested modern technologies. “Since it’s already been developed in oil and gas, we know what those remedies could look like.”

Tetraspar floating foundation

If floating systems are to help wind power achieve anything like the practically unrestricted capability anticipated by the IEA, business will certainly have to lower costs. Drifting introduces a whole new expenditure in the manufacture as well as installment of systems, partially since mooring cables get much more expensive as water gets deeper. Transportation prices could be reduced, because drifting systems can be towed from port rather than put up mixed-up, however that’s not nearly enough to counter the expense of a modern technology that isn’t designed for automation. “It’s not copy-paste from oil and also gas,” says Manahil Lakhmiri, head of overseas wind at Engie, which is working with California-based Principle Power Inc. on a drifting pilot project off Portugal. “What we see today is there’s one floater made every 3 months,” she includes. “We need one drifter weekly.”

That’s a problem Stiesdal has actually solved previously. The generators he aided leader showed fairly scalable– they came to be as prevalent as they did since their elements could be created swiftly and cheaply. His brand-new drifting system, referred to as TetraSpar as well as backed by oil giant Royal Dutch Covering Plc and German utility Innogy SE, aims to industrialize the market. He’s likewise collaborating with Welcon A/S, among the biggest wind turbine tower producers. That’s permitted Stiesdal, an independent developer, to create a prototype at factory rates.

His platform is primarily made with the same products as a wind turbine tower, with much of the labor at the Danish manufacturing facility done by robotics. Equipments turn out the steel and do most of the welding, while workers fit pieces together and also perform finishing touches. “It would certainly be rather very easy to mass-manufacture them,” says Rune Holm, a task manager at Welcon. “If you desire the automation, you should utilize some of the knowledge you already have.”

Stiesdal’s competitors consist of Norway’s Equinor ASA, the first programmer to obtain a drifting wind farm out on the water, a pilot task of five generators off the coastline of Scotland in the North Sea. The firm prepares to scale up with a bigger endeavor in Norway that’s expected to set you back about $500 million. Another major rival is Concept Power, which is backed by Spanish oil firm Repsol SA and also EDP Energias de Portugal SA. Principle has actually currently examined its layout in the Atlantic with a few of the largest turbines on the marketplace.

Despite having a mere handful of drifting pilot tasks out on the sea, power analysts predict rapid development to comply with quickly after the innovation is developed. If floating wind gets to 3.5 gigawatts by 2030, as BNEF projections, that rate would certainly track the one complied with by conventional overseas wind. Much will certainly depend on governments; offshore wind took off only with the help of aids, and it’s vague whether as well as in what type aid will continue.

Later this year, or potentially very early in 2021, relying on the effect of the coronavirus pandemic, a vehicle will certainly haul Stiesdal’s floating tool to the Danish shore. A boat will tow it to Norway. The next step would be to accumulate to evaluate a much larger wind turbine. If all goes well, the man that helped start the wind industry could leap to the front of the race for the following clean-energy breakthrough. The stakes, determined in increments of international temperatures, are rising fast. “The trajectory today is not also two levels– it’s a lot higher,” Stiesdal says. “The concept I’ve had myself was we need to change the concern from, ‘Exactly how can we afford it?’ to ‘Just how can we pay for not to?'”.